Handle the heat,

lighten the load

About ThermoPlate™

Who says plated plastics can’t last past 160°C (320°F)? Products from our ThermoPlate process can withstand the heat. This high-heat and strength solution uses injection molding and chrome plating to create products with a lighter carbon footprint wherever metal is used.

The ThermoPlate process takes a weight off designers as well, decorating tight contours with the brilliance of chrome. It is now possible to realize a harmonious look and complex geometries for any application, from automotive trim to consumer appliances, power tools and beyond.

Performance meets harmony

Harmonization across the vehicle has always been key to purchasing decisions. On the rear of the vehicle, temperatures near the tailpipe bezel can only be outlasted by heavy stainless steel. Any new material looking to lighten the load and keep a consistent aesthetic must also keep its cool past 160°C (320°F).

Harmonization across the vehicle has always been key to purchasing decisions. On the rear of the vehicle, temperatures near the tailpipe bezel can only be outlasted by heavy stainless steel. Any new material looking to lighten the load and keep a consistent aesthetic must also keep its cool past 160°C (320°F).

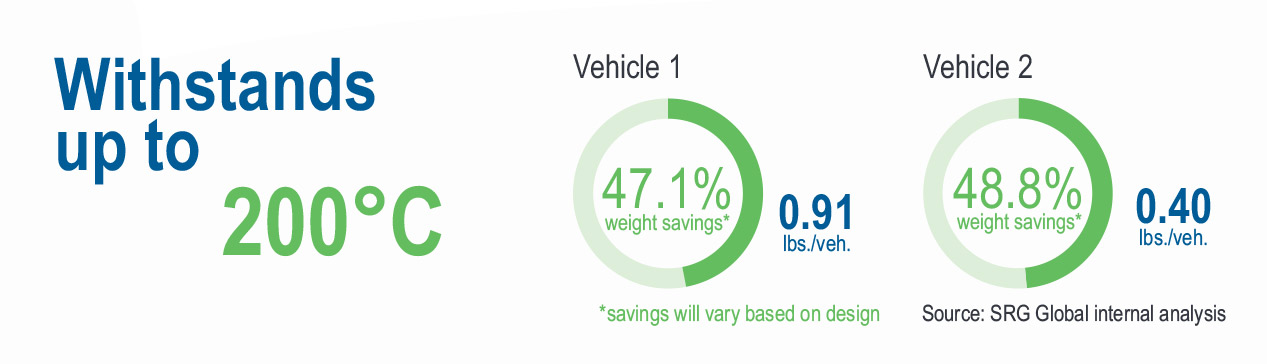

Our ThermoPlate process does just that and more, withstanding up to 200° C (392° F) and reducing exhaust tip weight 40-60% (relative to metal). Matching the color and gloss of surrounding trim, this solution delivers a difference you can see with your eye and feel in your pocket.

Road tested, industry recognized

After validation from our full-scale research and development center, bezels made from the ThermoPlate process hit the road. Proven to withstand extreme weight, temperature and incline, a global automaker recognized this solution as one of their top 15 new technologies in 2018.

After validation from our full-scale research and development center, bezels made from the ThermoPlate process hit the road. Proven to withstand extreme weight, temperature and incline, a global automaker recognized this solution as one of their top 15 new technologies in 2018.

Contact us for more information about ThermoPlate™.